Industrial Coffee Grinder for Bulk Coffee Production: What You Need to Know

Industrial Coffee Grinder for Bulk Coffee Production: What You Need to Know

Blog Article

Industrial Coffee Mill Overview: Increase Efficiency and Quality

In the affordable landscape of coffee production, selecting the ideal industrial coffee grinder plays a crucial duty in boosting both performance and product high quality. Comprehending the subtleties of numerous grinder types and essential functions-- such as personalized grind settings and durable building-- can considerably influence the last taste account of the coffee. The optimization of the grinding process, combined with attentive maintenance, is vital for maintaining efficiency over time. As we discover these crucial aspects, it ends up being noticeable that the effects extend beyond simple devices selection, influencing total business success in ways that require closer assessment.

Understanding Grinder Kinds

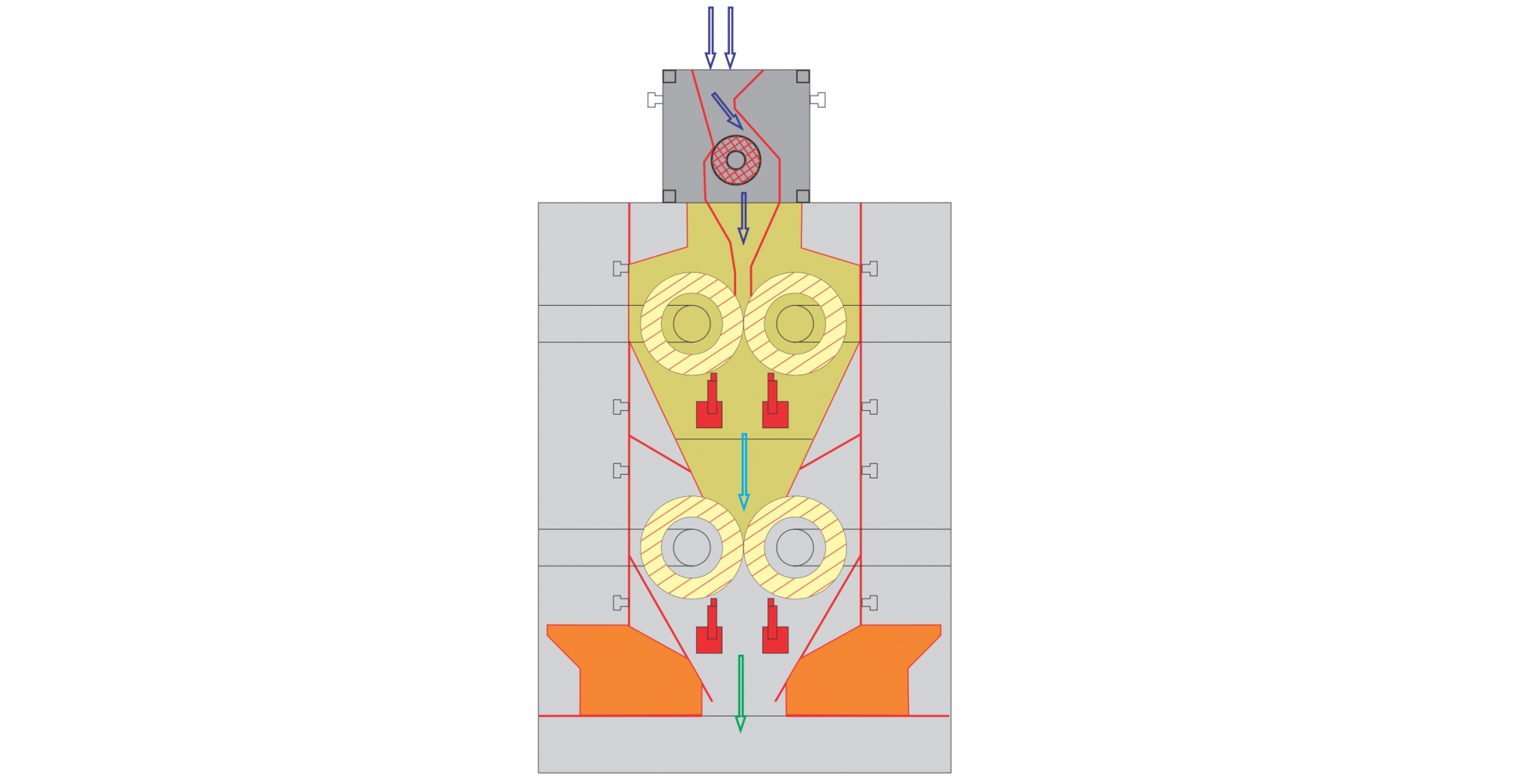

When picking a commercial coffee grinder, comprehending the various kinds readily available is important for maximizing both flavor removal and operational efficiency. The 2 primary kinds of mills are blade grinders and burr mills.

Ultimately, choosing the appropriate sort of mill is integral to preserving top quality and efficiency in coffee manufacturing, making it important for organizations to invest in top quality burr grinders for ideal outcomes.

Key Functions to Take Into Consideration

Selecting an industrial coffee grinder needs mindful consideration of several crucial attributes that can substantially affect both efficiency and the overall coffee experience. One of the main facets to review is the grinding mechanism. Burr grinders are normally liked over blade mills, as they provide a consistent grind size, which is critical for ideal removal and taste.

An additional essential attribute is the mill's capability. A flexible grinder with multiple settings permits you to customize the work dimension to different brewing approaches, boosting the coffee's taste account.

The construction material likewise plays a duty in resilience and upkeep. Stainless-steel elements usually supply durability and are much easier to clean up, which is crucial for keeping health standards. Last but not least, review the grinder's noise degree, particularly in a busy coffee shop or production setting, where extreme noise can be turbulent. Investing in a grinder that balances these functions can considerably boost both functional efficiency and the quality of the coffee offered.

Optimizing Grinding Process

To accomplish the ideal results in coffee prep work, enhancing the grinding procedure is essential. The work size dramatically affects removal, flavor, and overall high quality of the brewed coffee.

In addition, checking the grinding speed can maximize the process. Slower grinding frequently produces much less warmth, preserving delicate flavors and fragrances. Alternatively, much faster grinding might produce too much warm, adversely impacting the coffee's high quality.

Maintenance and Care Tips

Correct Web Site maintenance and treatment of commercial coffee grinders are essential for ensuring ideal efficiency and longevity. Normal cleaning is the structure of maintenance; deposit buildup can impact taste and grinding performance. It is advisable to cleanse the mill after each usage, wiping down the exterior and eliminating any coffee grounds from the burrs.

In addition, evaluate the grinding burrs for damage. Boring burrs can compromise grind consistency, so they ought to be changed as essential. Industrial Coffee Grinder. Occasionally adjusting the grinder is likewise crucial, as this maintains the preferred work dimension for different brewing methods

Lubrication of relocating parts should be performed according to the producer's requirements, as this decreases rubbing and prolongs the life of the devices. It is necessary to utilize food-grade lubes to ensure safety and conformity with health guidelines.

Finally, keep the grinder in a completely dry and stable atmosphere to stop corrosion and rust. By adhering to these maintenance and treatment suggestions, drivers can improve the performance of their industrial coffee mills while ensuring high-grade output and extended functional life.

Roi Evaluation

Assessing the roi (ROI) for industrial coffee mills is vital for companies seeking to optimize their coffee manufacturing capacities. A comprehensive ROI evaluation assists identify the financial feasibility of buying high-grade grinders, allowing organizations to evaluate the first prices versus potential gains.

To perform a detailed ROI evaluation, services ought to take into consideration numerous key factors. Initially, analyze the acquisition price of the mill, consisting of installation and any kind of needed alterations to existing framework. Next, determine functional prices, consisting of power consumption, upkeep expenditures, and labor effectiveness renovations. High-performance mills frequently cause decreased grinding time and raised throughput, which can significantly improve performance.

Furthermore, take into consideration the impact on product quality. Industrial Coffee Grinder. Superior grinders produce an even more regular work dimension, which can improve flavor profiles and consumer fulfillment, ultimately driving sales. By raising the high quality of the end product, discover this organizations can validate greater pricing, leading to boosted revenue

Final Thought

In recap, an industrial coffee grinder plays an essential function in improving both effectiveness and product high quality within coffee production. Inevitably, the critical financial investment in a trusted grinder contributes dramatically to improved profits and competition in the coffee industry.

In the affordable landscape of coffee production, selecting the best commercial coffee mill plays a crucial duty in improving both performance and product top quality. The two primary types of grinders are blade grinders and burr mills. Within the burr mill classification, there are flat burr mills and conical burr grinders, each with its benefits. Burr mills are usually chosen over blade grinders, as they offer a constant grind size, which is essential for optimum removal and flavor.

In summary, an industrial coffee grinder plays a critical function in enhancing both efficiency and product top quality within coffee manufacturing.

Report this page